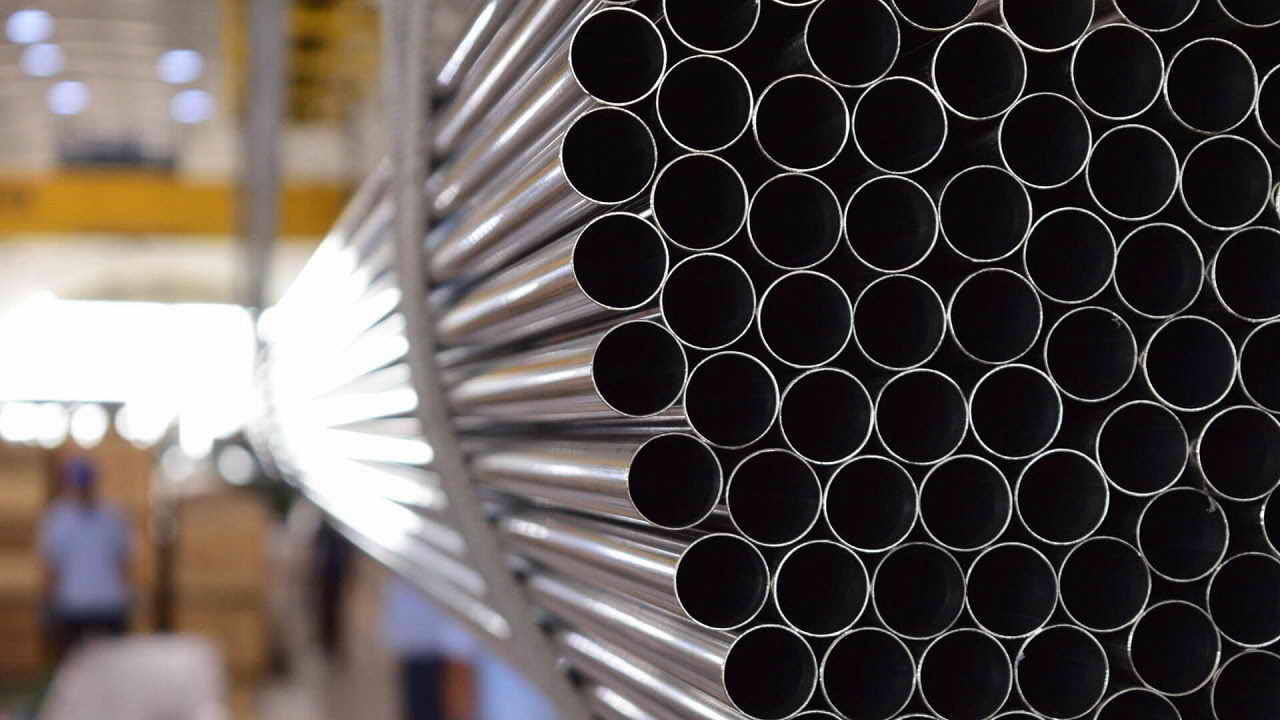

Extreme Epoxy Coatings strives to be the best mechanical contractor that specializes in industrial piping fabrication and installation. Process piping moves water, gases, fuels, chemicals, liquids, and other raw materials to systems that convert them into usable products.

It is a form of pipework used in manufacturing and industrial processes. Process piping is specially designed for specific applications to ensure it meets safety and health standards that suit the needs of given manufacturing processes.

The complex systems consist of gaskets, nuts, bolts, tubing, pipe supports, flanges, temperature control instruments, pressure control equipment, flow control instruments, control valves, and pipes. Not all tubes in a building are plumbing pipes.

The Difference Between Plumbing and Process Piping

The difference is the equipment connected to the pipe. A pipe connected to a faucet is part of a plumbing system. When connected to a food manufacturing machine, a drink machine, or used in an industrial factory process, it is likely process piping. A pipeline fluid is categorized into one of four groups.

- Stable, non-toxic, non-flammable fluids

- Toxic, unstable, flammable fluids

- Non-toxic, stable, non-flammable fluids

- Toxic, unstable, flammable fluids

A significant difference involves building codes. When installed and connected to water fixtures, such as showers and faucets, the pipe is regulated by plumbing codes. Engineering codes regulate process piping systems. Process piping systems generally do not carry water. Water may be an ingredient or a component for cooling.

Another way to explain the difference is – whatever is transported is used for specific processes that are not water distribution. Engineering codes typically regulate processing piping. Industrial facilities involved in the generation of power or the manufacture of products use process piping.

Business Use of Process Piping

Utility piping systems are used to support industrial processes that transport fuels, compressed air, water, steam, air, etc. Certain draining piping that is outside the realm of plumbing codes sometimes fits the classification of process piping. Obvious places that use a process piping system are:

- PULP AND PAPER PLANTS

- PETROLEUM AND CHEMICAL PLANTS

- PETROLEUM REFINERIES

- PHARMACEUTICAL MANUFACTURING FACILITIES

There are not so obvious places that use process piping. They include:

- WASTE TREATMENT FACILITIES

- WATER TREATMENT OPERATIONS

- AIRCRAFT AND AUTOMOTIVE PLANTS

- SEMICONDUCTOR FACILITIES

Designing Process Piping

The pipeline design stage includes planning the pipeline routine, choosing the pipe diameter to use, construction materials, and stress analysis. A hydraulic analysis determines the range of operational parameters. It provides the temperature and pressure profiles for given pipe flow rates, fluid properties, and sizes. The material is a fundamental issue decided at the conceptual stage of a project. Metallic pipeline materials are most frequently used.

Materials Used for Process Piping

Materials frequently used for piping include:

- Carbon steel

- Stainless steel

- Cast iron or ductile iron

- Galvanized pipe

- Titanium

- Copper

- Brass

- Plastic

- Alloy steel, such as a nickel-chromium combination, tungsten, or manganese

Low carbon steel is the industrial piping material that is most common. Stainless steel tubing and pipe are used to resist oxidation and corrosion, high temperatures, low maintenance costs and cleanliness, and maintaining the purity of material in contact with it.

Cast iron is wear-resistant and has high compressive strength. It lacks impact strength, malleability, and ductility. Galvanized pipe has a thin layer of zinc coating that increases the pipe’s lifespan by protecting it from corrosion and rust. Titanium has excellent corrosion resistance, particularly useful for seawater duties of heat exchangers tubes and piping.

When ease of fabrication is of importance, copper tubing is used. Brass is resistant to seawater attack. It is used in diverse process plants that transfer seawater under turbulent conditions because it resists corrosion and impingement. Polyethylene and PVC are two types of plastic pipes commonly used. Polyethylene is a flexible, lightweight pipe generally joined by heat fusion. It typically does not leak. PVC is joined by solvent cement. It is exceptionally corrosion-resistant.

Why Choose Extreme Epoxy Coatings

If you are uncertain if process piping needs repair, Extreme Epoxy Coatings can help. We can design and upgrade piping systems to better meet your facility’s needs. We have been a partner to our customers for 15 years. Everyone is driven by the mission to exceed expectations.

In Turlock, CA, finding an architect that is a general contractor can be difficult. We coordinate with architects to ensure the agreed design for projects and suggest ways to make designs safe and stable. In turn, we ask for suggestions to create a design come alive. Look at our website for the services our engineers provide for the project you have in mind.